Blogs

Blog Categories

RV carport height isn’t something you want to eyeball or guess. Being off by even a small amount can turn into a daily hassle. Before committing to a design, the smartest move is to measure your RV yourself and work from real numbers instead of assumptions.

Key Highlights

- RV height should always be measured by hand, not pulled from a brochure

- Roof accessories often make RVs taller than expected

- Clearance matters just as much as the RV’s actual height

- Roof style changes how much usable space you have inside the carport

- Planning ahead helps avoid rebuilding later

Finding Your RV’s Overall Height

This part matters more than anything else. Many RV owners assume they already know their rig’s height, but real-world measurements are often different. Add-ons, ground conditions, and even tire wear can change things. Taking a few minutes to measure properly now can prevent expensive mistakes later.

- Measure RV Height

Park your RV on flat ground and grab a tape measure. Measure straight up from the ground to the tallest point on the roof. This usually isn’t the roof itself, it’s the air conditioner, vent cover, antenna, or satellite dish. Measure slowly and double-check your work.

- Add Clearance

Once you have the true height, don’t stop there. Add some clearance. Most people aim for an extra 6 to 12 inches. That buffer helps with uneven slabs, suspension movement, and pulling in without stress. It also gives you flexibility if you add gear later.

- Convert RV Height to Recommended Leg Height

Your RV height plus clearance gives you a target number. From there, roof style and pitch come into play. Those factors determine how tall the legs need to be so the lowest point of the roof doesn’t interfere.

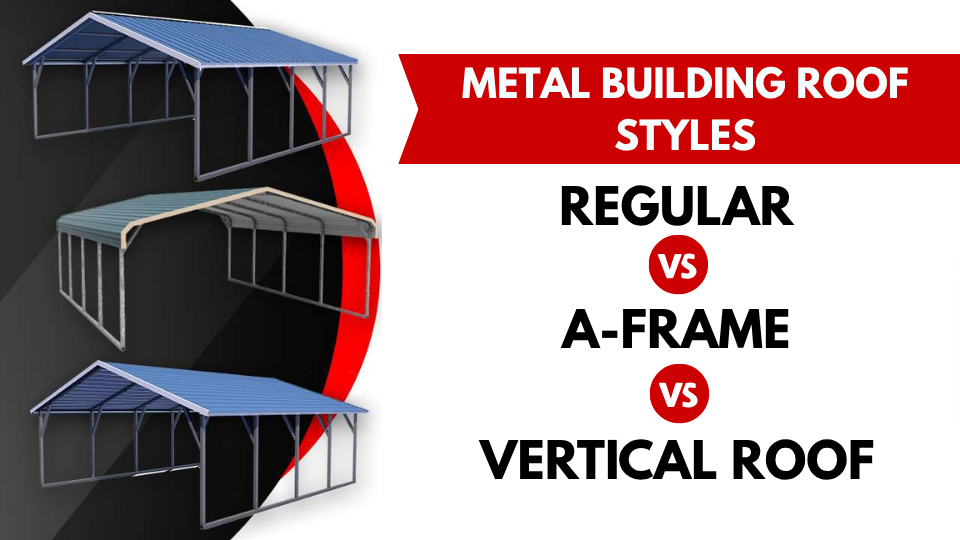

Roof Style and Usable Height

Two carports can have the same leg height but very different interior clearance. The roof shape changes everything. Let’s look at some of the common styles and how they affect your interior height:

- Regular Roof

Regular roofs have a softer curve and lower pitch. You get decent height in the middle, but usable clearance drops near the sides. It works for shorter RVs, less so for taller ones.

- A-Frame Roof

A-frame roofs use a sharper pitch. That gives you better center clearance without dramatically increasing leg height. It’s a common upgrade when RV height is close to the limit.

- Vertical Roof

Vertical roofs have the steepest pitch. They offer the most usable height overall and handle rain and snow better. For tall RVs, this option leaves the most breathing room.

Common RV Height Ranges

Most RVs fall into a general height range, but accessories can push them higher. These ranges give you a starting point.

| RV Type | Typical Height | Suggested Carport Leg Height |

|---|---|---|

| Travel Trailer | 10’–11’ | 12’ |

| Fifth Wheel | 12’–13’ | 14’ |

| Class C Motorhome | 11’–12’ | 13’–14’ |

| Class A Motorhome | 12’6”–13’6” | 14’–16’ |

A Checklist for RV Carport Prep

Before installation, it helps to slow down and look at the site itself. A solid plan makes the build smoother and prevents last-minute changes that cost time or money.

- Site prep – Make sure the ground is level and accessible

- Slab thickness – Concrete should support both the RV and anchors

- Drainage – Water should flow away from the pad, not pool

- Gutters – Helps control runoff and protect the slab edge

- Future needs – Consider taller RVs or partial enclosures later

Design Your RV Carport the Right Way with Our 3D Designer

Designing on paper only gets you so far. Using the 3D designer lets you actually see how leg height, roof pitch, and layout work together. You can tweak dimensions, change roof styles, and catch issues before anything is built. All from home, on your schedule.

Try our 3D Designer to get a custom RV carport quote matched to your zip code.

Carport Height Matters

RV carport height isn’t about picking a random number. It’s about knowing your RV, allowing for clearance, and choosing a roof style that gives you usable space. Measure carefully. Plan for the future. When those pieces line up, your finished carport fits the way it should, without stress or second guesses.

Want to know more about picking the best height for your RV carport? Call our experts at (208) 572-1441 to get started.

When buyers start talking about building height, the conversation can get confusing fast. One person is thinking about wall height. Another is focused on the roof peak. Someone else just wants enough room inside to park equipment. All of those ideas fall under “height,” but they’re not the same thing.

On top of that, local building departments set rules that can override personal preferences. Those rules are usually tied to wind exposure and snow load. Whatever height you settle on has to work within those limits.

Key Highlights

- Building height is measured in more than one way

- Sidewall height doesn’t always equal usable space

- Roof pitch affects total height more than expected

- Doors often determine minimum wall height

- Local codes influence allowable height

- Wind and snow loads are tied to height calculations

Metal Building Heights

Not all height measurements serve the same purpose. Some are used when ordering a building. Others come into play during engineering and permitting. Understanding the difference early helps avoid revisions later. Below, we break down these metal building heights:

Sidewall Height

Sidewall height is measured from the finished floor to the eave. This is the number most buyers reference when choosing a building. It impacts door placement and wall clearance, but doesn't include the roof structure.

Peak Height

Peak height runs from the floor to the highest point of the roof. It changes based on roof pitch and building width. Zoning regulations often reference this measurement.

Clear Height

Clear height describes the open vertical space inside the building. Framing, purlins, and insulation reduce it slightly. This is the height that matters for lifts, racks, and tall vehicles.

Mean Roof Height

Mean roof height is the average between the eave and the peak. Engineers use it when calculating wind and snow loads. It's rarely discussed by buyers, but it matters behind the scenes.

Roof Pitch and Type

Roof design plays a quiet but important role in overall building height. A small change in pitch can add noticeable height at the peak. Roof type also affects how weather loads are handled.

Gable Roof

Gable roofs slope up from both sidewalls and meet at the ridge. They're common because they balance loads well and provide extra height near the center.

Single-Slope Roof

Single-slope roofs rise from one side to the other. They're often chosen when height limits apply or when drainage needs to move in one direction.

Gambrel Roof

This roofing type offers a bit more headroom thanks to its four-panel roofs that are arranged in a barn-like arc.

Common Roofing Styles

- Regular Roofing: This is your basic roofing style. It’s economical and great for general storage, but isn’t designed to handle more than moderate weather.

- A-Frame Roofing: This roof features a steeper pitch and is much more suited for rain and snow.

- Vertical Roofing: Vertical roofing features vertically arranged panels that allow snow and storm debris to slide off your roof. It's one of the most expensive options, but it provides the best functionality.

Door Height and Equipment Clearance

Doors are where height issues usually show up first. A building can seem tall enough until tracks and framing are installed, so planning for clearance avoids that problem.

Roll-up Door Height

Roll-up doors need space above the opening for tracks. A door listed at 12 feet typically requires additional wall height.

Framed Openings

Framed openings allow flexibility in door size and placement. They also affect how loads are distributed around the opening.

Oversized Vehicles

Taller vehicles, such as RVs, trailers, and motorhomes, require more than door clearance alone. Interior framing and roof slope reduce usable height.

Choosing the Right Height by Use

Height should match how the building will actually be used. Storage needs, access, and future plans all factor in.

| Building Type | Typical Height Range | Common Use |

|---|---|---|

| Residential Metal Garages | 8’–10’ | Vehicles and workshops |

| RV Storage | 12’–16’ | Motorhomes and trailers |

| Metal Barns | 10’–14’ | Equipment and livestock |

| Commercial Metal Buildings | 12’–20’+ | Operations and storage |

Why Building Height Matters for Wind and Snow

Building height affects how wind and snow interact with the structure. Taller walls catch more wind. Roof height changes how snow accumulates. Local building officials account for this when setting requirements.

- Wall height impacts wind exposure

- Roof height affects snow drift (ground snow loads map)

- Mean roof height is used in load calculations

- Taller buildings may need added bracing

EMB Metal Buildings can help guide you through these requirements and plan a building that meets local codes. Call us today at [phone number] for more information.

Quick Height Planning Checklist

Before finalizing height, it helps to think through real-world use.

- Purpose of the building

- Door sizes

- Interior clearance needs

- Local zoning limits

- Wind and snow load rules

- Roof pitch selection

Design Your Own Building in 3D with EMB Metal Buildings

EMB Metal Buildings offers a 3D Design Tool that lets you plan your building from home. You can adjust height, roof style, doors, and more to perfect your structure’s layout in real-time. Once you’re done, simply send the final design to our building experts for a FREE quote.

When people hear certified metal building, they often assume it’s just a quality label. In reality, certification means your building has been engineered to meet the local building codes where it’s going to be installed. That’s a big deal, because those codes control whether a permit can be issued in the first place.

Permits are where most metal building projects either move forward smoothly or hit a wall. Counties, cities, and townships all follow different rules, and many won’t even review an application unless certified plans are included.

Once you understand how certification ties into wind loads, snow loads, and permitting, the process feels a lot more manageable. It stops being guesswork and starts becoming a checklist.

If you’re also budgeting a larger shop or storage build, see our full cost breakdown here: 40x60 Metal Building Cost in 2026: Real Price Ranges + What’s Included

Key Takeaways

- Certification means your building is engineered for local code compliance

- Most building departments require stamped plans before reviewing permits

- Wind and snow loads are calculated using ASCE and IBC standards

- Load requirements can change drastically between nearby locations

- Non-certified buildings often stall or fail during plan review

- Having documents ready upfront avoids repeat submissions

What Certified Metal Buildings Really Mean

A certified metal building is designed for where it will actually stand. Instead of relying on generic specs, your building is reviewed against local wind speeds, snow loads, exposure conditions, and intended use.

Certified vs. Non-Certified Buildings

Engineering Behind the Design

Certified buildings include calculations stamped by a licensed engineer. Non-certified buildings often rely on standard layouts that don't account for site-specific forces.

Permit Compatibility

Certified plans are typically accepted by building departments without major revisions. Non-certified plans often trigger requests for re-engineering or added documentation.

Structural Reliability

Certification confirms the building can resist uplift, drifting snow, and lateral pressure. Without it, performance is largely assumed rather than proven.

Future Flexibility

Certified buildings are easier to insure, modify, or sell later. Non-certified structures can create issues during inspections or upgrades.

Permitting 101 for Metal Buildings

Every permitting journey starts with the local authority having jurisdiction. This could be a city, county, or regional building office. Their job is to confirm that your building meets zoning rules and safety codes before construction begins.

To get started, you’ll usually submit engineered plans, site information, and load data for review. Once approved, the permit allows construction to legally move forward.

What you’ll typically need:

- Engineered and stamped building plans

- A site or plot plan

- Wind and snow load documentation

- Intended use and occupancy details

- Foundation information

Who to contact:

Start with your local building department or planning office. They can tell you exactly what they expect before anything is submitted.

Wind Loads Explained

Wind loads aren’t based on a single wind speed number. Engineers look at several factors, including exposure category, building height, roof shape, enclosure type, and risk classification, to make their determination. All of this falls under ASCE and IBC regulations, which most jurisdictions follow.

Changing something as simple as door size or roof pitch can shift the required wind rating. That’s why accurate information matters early on.

Call EMB Metal Buildings at (208) 572-1441 for local wind/snow load certification options.

Details to Confirm for Wind Load Engineering

| Item | Reason |

|---|---|

| Jobsite address | Determines local wind zone |

| Building use | Sets risk category |

| Roof style | Affects uplift forces |

| Eave height | Impacts wind exposure |

| Openings and doors | Influences internal pressure |

| Exposure rating | Accounts for surrounding terrain |

Metal Building Snow Loads

Snow load requirements take into account elevation, roof geometry, and drifting patterns. As a result, two towns in the same state can end up with very different requirements.

Roof Snow Load

This measures how much snow the roof must support. Roof slope, heat loss, and drifting all influence the final value.

Ground Snow Load

Ground snow load reflects historical weather data for a specific area and serves as the starting point for calculations.

Dead Load

Dead load accounts for the permanent weight of the building itself, including framing and panels.

Live Load

Live load includes temporary forces such as workers, tools, or short-term equipment on the roof.

Documents Required for Building Permits

Most permit issues live and die by the paperwork. Missing documents usually mean delays, which can impede your project timeline. For the smoothest results, you’ll want to have the following available when submitting an application:

- Engineered, stamped building plans

- Site or plot plan

- Wind and snow load calculations

- Foundation drawings

- Zoning or land-use approvals, if required

- Completed permit applications

Permit and Certification Checklist

Running through this quick checklist before submitting can prevent weeks of back-and-forth with the building department:

Checklist

- Contact local permitting authorities

- Confirm zoning and setbacks

- Define building use and occupancy

- Select building size and layout

- Choose roof style and eave height

- Verify wind and snow load requirements

- Choose foundation type

- Prepare site grading and access

- Compile all engineered documents

Common Reasons for Delays and How to Avoid Them

Delays usually happen when documentation is missing, information is off, or plans fail to meet requirements. Some of the most common issues include:

Generic Load Ratings

Submitting non-specific wind or snow data often leads to rejection. Site-specific calculations are expected.

Incomplete Site Information

Missing elevations or property details can stall reviews quickly.

Zoning Oversights

Structural approval doesn't override zoning restrictions. These need to be addressed early.

Foundation Conflicts

If foundation plans don't match engineered loads, revisions are almost guaranteed.

Metal Building Permit Costs

Permit costs vary by location, but most metal building projects fall into predictable ranges. Fees usually reflect review time, engineering requirements, and administrative processing.

| Cost Item | Typical Range |

|---|---|

| Permit application | $100 – $500 |

| Plan review | $200 – $1,000 |

| Engineer-stamped plans | $500 – $2,500 |

| Zoning or impact fees | $0 – $1,500 |

| Revisions or resubmittals | $150 – $600 |

FAQs About Certified Metal Building Permits

Knowing the basics upfront helps avoid surprises once the permit process begins. To give you the smoothest experience, we’ve answered a few of the questions we get most often:

What does the term certified metal building mean?

Answer: Certification means the building is engineered to meet local code requirements for safety and structural performance.

Do I always need a permit for a metal building?

Answer: Most permanent or occupied structures require one, even for agricultural or storage use.

Is a wind mph rating enough for a permit?

Answer: Usually not. Building departments expect full ASCE-based calculations.

What is metal building snow load, and why does it matter?

Answer: It guarantees the roof can safely support accumulated snow without structural failure.

Will certified plans guarantee approval?

Answer: They improve approval odds, but zoning and site compliance still apply.

Do 40x60 metal buildings require different wind/snow considerations?

Answer: Yes. Larger footprints and wider spans often increase load requirements.

A lot of people focus on the building package and forget what’s underneath it. That’s usually where the problems start. With a 40x60 metal building, the site work and the slab matter just as much as the steel. Sometimes more.

This page talks through what actually goes into site prep, what concrete work tends to cost, and why two projects that look the same on paper rarely price out the same in real life.

Key Takeaways – TL;DR

- Ground work can make or break a 40x60 project

- Concrete slabs are the most common foundation choice

- Soil, slope, and drainage change pricing fast

- Slab design matters more than people expect

- Slab and site prep costs are separate from 40x60 metal building prices

- Planning early avoids rework later

What Site Prep and Slab Work Really Includes

Site prep isn’t always clean and simple. Every property has quirks. Slight slopes. Soft spots. Access issues. For a 40x60 metal building, those details show up quickly once equipment hits the ground.

Clearing

Clearing means more than cutting grass. Trees, roots, brush, and old debris all have to go. Some sites take a day. Others take much longer.

Grading

The ground needs to be level and compacted so the slab stays put. If this step is rushed, cracks and settling tend to show up later.

Access

Concrete trucks don't squeeze into tight spaces easily. Long driveways, soft soil, or limited turnarounds can add cost without warning.

Foundation

This is the forming, reinforcement, and pour. The slab has to line up with the building layout and meet local requirements.

Common Foundation Types for 40x60 Metal Buildings

Most 40x60 buildings sit on concrete slabs. They’re solid, durable, and work well for enclosed structures. Other foundations exist, but they’re usually chosen for specific reasons, not convenience. These include:

- Soil and Gravel Foundations

Gravel bases are sometimes used for open buildings or storage. They're cheaper upfront but don't offer a finished floor or long-term stability.

- Asphalt Foundations

Asphalt shows up occasionally, usually in commercial settings and for residential carports and garages. It’s less common and doesn’t perform like concrete under constant load.

Budget Ranges for a 40x60 Metal Building

As a general range, a 40x60 metal building usually runs $11 to $25 per square foot for the base structure, with site prep and slab work added separately. These costs include:

| Average Price Range | |

|---|---|

| 40x60 Metal Building (Base Model) | $26,400 – $60,000 |

| Site Prep | $4,000 – $15,000 |

| Concrete Slab | $12,000 – $30,000 |

Site Prep Checklist

Before concrete shows up, a few basics should already be handled to prevent delays:

- Clear vegetation and debris

- Level and compact the site

- Plan drainage paths

- Decide where utilities enter

- Make sure trucks can access the site

- Pull required permits

- Use experienced concrete contractors

Cost Drivers for Concrete Slabs

Concrete costs don’t jump randomly. They rise because of:

- Thicker slabs and reinforced edges

- Rebar, mesh, and spacing requirements

- Soil prep and compaction work

- Vapor barriers and moisture control

- Wind, snow, or seismic codes

- Labor and material pricing in your area

Common Mistakes When Planning Foundations

Most foundation issues start long before the pour. Keep your eyes out for the following to minimize headaches or delays:

Slabs poured too thin

Thin slabs don’t hold up under real use. Cracks usually follow. That’s another reason it pays to hire professional contractors.

No drainage plan

Water around a slab leads to erosion and movement over time. Plan your drainage well ahead of time to reduce flooding and erosion.

Skipping soil prep

Bad soil doesn't fix itself. Test and compact your soil before laying a foundation.

Pouring before the building is finalized

Building plans can change, but if you’re locked into a concrete pad size, you may be in for major headaches.

EMB Metal Buildings Is Your Partner for Durable Metal Buildings

EMB Metal Buildings has years of experience delivering high-quality metal buildings. Our structures are certified against the wind and snow in your region, customized to fit your project type, and built to last for years, keeping your things safe.

If you’d like to speak to one of our building experts, call us today at (208) 572-1441. Or design your building on your own with our 3D Designer tool.

FAQs About Metal Building Site Prep

Do you have questions about preparing your building site for a 40x60 metal building? We want you to be sure when you buy, so we’ve answered a few of the most common questions on the subject:

- How much does a 40x60 concrete slab cost?

Answer: Most land somewhere between $12,000 and $30,000, depending on thickness, reinforcement, and site conditions.

- How thick should a slab be for a fully enclosed 40x60 metal building?

Answer: Four to six inches is common, often with thicker edges. Local codes can change that.

- Should my slab be bigger than the building?

Answer: Sometimes. Extra space can help with drainage and future use.

- Do I need a vapor barrier under a slab?

Answer: Often yes, especially for enclosed buildings.

- What site prep should be done before the crew arrives?

Answer: The site should be cleared, leveled, compacted, and accessible.

- How do wind and snow codes affect the slab?

Answer: Higher loads usually mean more reinforcement and thicker concrete.

- Can I pour concrete before finalizing the building design?

Answer: That’s risky. Final plans should be set before the pour.

A 40x60 metal building gives you 2,400 square feet. That’s enough room to park equipment, move around comfortably, and still have space left over. That’s why this size keeps coming up again and again.

40x60 Metal Building Prices in 2026

40x60 metal building not too small, and not too big. For a lot of buyers, it’s a safe size that works in almost any application. In 2026, though, pricing isn’t as simple as grabbing a flat rate and moving on. Design choices, location, and site conditions all affect the final number, and knowing what to look for can save you big time.

This guide lays out realistic costs and what’s usually included with your purchase.

Key Takeaways (TL;DR)

- What a 40x60 building actually gives you in usable space

- Why this size works for so many different applications

- General price ranges you’ll see in 2026

- What’s normally part of the base package

- Common items that increase the total cost

- How local requirements quietly affect pricing

How People Use a 40x60 Metal Building

Most people don’t build a 40x60 with just one narrow plan in mind. They pick it because it keeps options open. These buildings are regularly used for:

Agriculture

On farms and rural properties, this size is often used for equipment, feed, or storage. There’s enough width to move machinery without constantly backing up and repositioning.

Residential Vehicle Storage

RVs, boats, trailers - this size handles all of it. Many owners are surprised by how much extra room they still have once the main vehicle is parked.

Workshops

A 40x60 works well as a shop because everything doesn’t end up stacked together. Tools, benches, and work areas can spread out instead of competing for space.

Commercial Projects

Contractors and small businesses use this size for storage, staging, or light operations. It’s large enough to function professionally without feeling oversized.

What’s Included in a 40x60 Metal Building Price

There’s no single correct price for a 40x60 metal building. In 2026, most buyers fall somewhere between $11 and $25 per square foot for a base structure.

That range usually covers the building shell, not the entire finished setup. Below, we’ll explore what’s included in a base metal building and what’s not:

| What’s Included | What’s Not Included |

|---|---|

| Steel framing and main structure | Concrete slab or foundation |

| Roof and wall panels | Site prep or grading |

| Trim, fasteners, anchors | Electrical or plumbing |

| Basic engineering | Permit costs |

| Standard load ratings | Insulation upgrades |

The 5 Biggest Cost Drivers for 40x60 Metal Buildings

Two buildings with the same footprint can end up priced very differently. These are the usual reasons.

Size

Your building size will be the number one factor that influences its cost. The bigger the building, the higher its price tag will be.

Roof Style

Boxed eave roofs are usually cheaper and work fine in many regions. Vertical roofs cost more but handle rain and snow better over time.

Doors

You’ll be able to choose the size and number of roll-up doors and walk-in doors for your structure, but it will affect its overall cost.

Foundation Prep

Clearing your building site and laying a foundation are a large part of your total metal building project price.

Insulation

Insulation isn’t required, but it changes how the building can be used. Higher insulation levels raise the upfront cost but can improve comfort and do more for keeping your vehicles safe from moisture.

Permits, Engineering, and Why Your Zip Code Matters

Location plays a bigger role than most people expect. Two identical buildings can have very different requirements depending on where they’re built, and two different prices.

Some areas require stamped plans or specific anchoring systems. Those requirements affect engineering and material specs.

Higher wind or snow ratings mean heavier framing and more bracing. That increases cost, but it also increases durability. (ASCE Hazard Tool)

FAQs About 40x60 Metal Building Costs

How much is a 40x60 metal building per square foot in 2026?

Answer: Most land costs between $11 and $25 per square foot, depending on options and location.

What’s included in a metal building kit?

Answer: Usually, the steel structure, panels, trim, fasteners, and basic engineering. Foundation and installation are separate.

Do I need a concrete slab for a 40x60?

Answer: Not always. Agricultural and storage buildings often use gravel. Shops and garages usually use concrete.

How much does a concrete slab cost per square foot?

Answer: Most slabs fall between $6 and $10 per square foot, depending on thickness and site conditions. (ACI concrete floor & slab guide, NRMCA joints in slabs-on-grade)

Does wind or snow rating change the price?

Answer: Yes. Higher ratings require stronger materials and additional engineering.

How long does delivery and installation take?

Answer: Delivery usually takes a few weeks. Installation can range from several days to a couple of weeks.

Most people don’t set out to buy a carport. They just reach a point where leaving things exposed stops making sense. Sun damage. Weather. A vehicle that’s nicer than the one before it. That’s usually what spurs an owner to start mulling over a structure.

Metal carports offer some of the most appeal because they’re simple. However, where people get caught off guard is the cost. Your structure’s size, roof style, ground conditions, and local rules will all have a say in the final price tag.

If you’re actively shopping, start here: explore EMB’s metal carports and compare options in the Shop as you read.

What’s the Difference Between a Carport and a Metal Garage?

Carports and garages serve different purposes, even when they look similar from the road. How do they differ?

- Carports are open. Posts, a roof, and airflow on the sides.

- Metal garages are enclosed, with walls, doors, and framing to match.

- Carports cost less because there’s less steel and less labor involved.

- Garages cost more, but you gain security, storage, and full weather protection.

Want enclosed storage instead? See EMB’s metal garages for common sizes, layouts, and use cases.

The Cost of a Carport in 2026

In most cases, you can expect a metal carport to range between $11 and $25 per square foot, depending on the structure and the add-ons you choose.

(For additional national cost benchmarks, see the sources linked below.)

| Type | Typical Size | Average Price Range |

|---|---|---|

| Single-Car Carport | Around 12’ x 20’ | $2,640 – $4,800 |

| Two-Car Carport | Around 18’ x 25’ | $4,950 – $9,000 |

| Three-Car Carport | Around 24’ x 30’ | $7,920 – $14,400 |

| RV Cover | Wider and taller, 35' to 45' long | $4,000 – $9,000 |

Shopping tip: if you already have a target size, you can browse size-focused pages like Two-Car Carports or Three-Car Carports.

What Affects a Carport’s Price?

In the end, two similar-looking carports can end up priced very differently.

Things that tend to move the price:

- Size

Wider spans and taller legs use more steel.

- Roof Style

Regular roofs cost less; vertical roofs add cost but handle weather better.

Need help deciding based on weather? Use EMB’s guide to check snow and wind loads.

- Steel Thickness

Heavier gauge steel raises the price and the strength.

- Enclosure Level

Even partial sides or end panels change the material and labor needs.

Foundation Costs

The ground underneath the carport doesn’t get much attention, but it should. Poor site prep causes more headaches than almost anything else.

Common site-related costs include:

- Clearing and Grading

You’ll need to clear and grade the site to guarantee that it’s level.

- Drainage

Choose a location that sits above natural water runoff and design ample drainage to prevent flooding.

- Foundation Options

Pick between soil, gravel, asphalt, and concrete slab foundations depending on your needs and budget.

For a step-by-step checklist, use EMB’s Site Preparation Guide.

- Permits

Some building officials will want drawings, load ratings, or certification paperwork. This can affect your project costs.

Carports vs. Metal Garages

Even at the same size, metal carports and garages are built differently and carry their own advantages:

| Carports | Metal Garages | |

|---|---|---|

| Starting Cost | Lower | Higher |

| Materials | Roof, Columns | Roof, Columns, Walls, Doors |

| Permitting | Often simpler | Stricter |

| Best for | Standard vehicle coverage | Securing vehicles and equipment |

If your priority is security and storage (tools, equipment, inventory), start with metal garages. If your priority is fast coverage at a lower entry cost, start with metal carports.

Budgeting Your Metal Carport Project

Most budget issues come from changes made late in the process. Planning ahead keeps costs predictable.

A few ways people keep prices in check:

- Choose the right size early, even if it feels slightly larger than you need today.

- Match the roof and foundation to your climate, not just appearance.

- Handle site prep correctly so installation doesn’t stall or need rework.

If you need flexible payments, review EMB’s Rent-to-Own program.

EMB Metal Buildings Is Your Source for High-Quality Metal Carports

A carport may be simple, but choosing the wrong one can still be expensive. Getting the size, height, and roof right the first time makes a huge difference long term. And EMB Metal Buildings wants to help you get the best structure for the job.

Every metal carport and garage we design is engineered to hold up to local wind and snow requirements, and made to last for decades with the right care. It doesn't matter whether you're designing a backyard boat cover or a massive commercial garage; we can make it happen.

Next steps:

- Design and compare options in the Shop

- Learn what happens after checkout in the Ordering Process

- Confirm local loads using the ASCE Hazard Tool (also referenced in EMB’s load-check guide)

Call our experts today at (208) 572-1441 for a full tour of our design process. We’ll answer all your questions and help you create the structure you’ve been waiting for.

FAQs about Metal Carports

Once metal carport pricing comes up, the same questions usually follow. So, we've gone ahead and answered the ones we see the most:

How much does a carport cost on average?

Answer: Many standard builds land somewhere between $1,500 and $4,000 depending on size and options, but installed pricing can vary a lot by region, site conditions, and certification needs. (See sources below.)

How much does a metal carport cost installed?

Answer: Installation is often included, but the total cost depends on site prep and foundation needs.

What size carport do I need for a truck or SUV?

Answer: Most trucks and SUVs are comfortable in a carport at least 12 feet wide and 20–25 feet long.

Does a carport need a concrete slab?

Answer: Not always. Many are installed on gravel or with ground anchors.

Do I need a permit for a carport, and what will the building department ask for?

Answer: That depends on the location. Expect questions about size, placement, and wind or snow ratings. Many jurisdictions reference code language similar to the IRC “carports shall be open on not less than two sides.” (Reference: IRC R309.2)

What is a certified carport, and when is it required?

Answer: Certified carports meet specific engineering standards and are often required in regulated areas or higher wind/snow regions. A quick first step is checking your local loads with the ASCE Hazard Tool.

What roof style is best for snow or heavy rain?

Answer: Vertical roofs tend to perform better in harsher weather because they shed water and snow more effectively.

Can I enclose a carport later, and how does that affect permitting?

Answer: Usually yes, but enclosing it can trigger new permit requirements. Planning ahead helps.

If you’re trying to decide between a metal carport and a metal garage, the right answer depends on how you use your space, your weather, and how much security you actually need. Both protect vehicles and equipment, but they solve different problems.

Carports vs. Garages

While many folks may lump metal carports and metal garages into the same category, these building types serve two distinct purposes and offer different advantages for their owners. One provides coverage from sun and rain, while the other delivers enclosed security.

Which one is right for you? That can be a hard question to answer. But with the right information, you can make the best choice for your next project.

Below is a real-world look at how metal garages and metal carports stack up, and which features matter most for your property.

What’s the Difference Between a Metal Carport and a Metal Garage?

Metal garages and metal carports are very similar in many regards, but they serve different functions. Both offer coverage, but only one provides true security.

- Metal carports are open, usually with a roof and exposed sides. (Explore: Metal Carports)

- Metal garages are fully enclosed, wall-to-wall. (Explore: Metal Garages)

- Metal garages have doors and can include windows, which allow you to lock them and control airflow.

- If you’re storing anything you’d be upset to lose, a garage makes more sense than a carport.

- Combination buildings split the difference, offering open parking with enclosed sections for storage or equipment. (See: Utility Buildings)

Comparing Metal Garages and Metal Carports

How do metal garages and metal carports stack up against one another?

| Feature | Metal Carports | Metal Garages |

|---|---|---|

| Weather Protection | Good for sun and light rain | Handles wind, rain, snow, and debris |

| Security | No real barrier | Enclosed and lockable |

| Storage Capability | Limited and exposed | Works for tools, vehicles, and equipment |

| Permitting Likelihood | Often easier | More likely to require permits |

| Project Timeline | Faster install | Takes a bit longer |

9 Real-World Factors That Can Help You Decide Which Is Right for You

Still unsure about which structure type is best for you? Below are real-life scenarios that can help you choose.

- Local Weather

If weather is mild most of the year, a carport can be enough. If you deal with heavy snow, strong wind, or regular storms, a garage tends to earn its keep. (Helpful: Snow & Wind Load Guide)

- Security Needs

Carports are convenient. They’re also wide open. Garages give you a door to close and lock, which is the first and foremost need for security.

- Moisture and Condensation

Open sides help moisture move through naturally. Garages can work just as well, but ventilation becomes something you actually have to think about.

- Access and Workflow

Carports are easy. No doors. No steps. Garages are better when you want order, separation, or a place to work without exposure.

- Budget

Carports usually cost less up front. Garages cost more, but you’re paying for walls, security, and usable indoor space. (Options: Financing and Rent-To-Own)

- Future Needs

Most people underestimate how quickly storage grows. Garages handle change better. Carports work best when the plan is simple and stays that way.

- Permits

Carports often slide through with fewer questions. Garages don’t always. Local rules matter here more than anything else.

- Site Prep

Carports are lighter and simpler. Garages need a bit more prep to support walls, doors, and enclosures. (Prep tips: Site Preparation)

- Resale Value

A garage usually feels like real square footage to buyers. A carport feels more temporary, even when it’s well-built.

Best Picks by Case

Some situations can make the choice between a metal carport and a garage pretty easy.

- Homeowners

If you just want coverage, a carport works. If you want storage, workspace, or something that feels permanent, a garage fits better.

- RV Owners

Carports are common because of their height and easy access. Garages make sense for smaller RVs or long-term storage. (Explore: RV Carports)

- Farm and Ranch

Carports are great for equipment that’s in and out all day. Garages are better for tools, supplies, and anything that can’t get wet.

- Small Businesses

Garages offer flexibility and are ideal for storage, inventory, equipment, and even light work. Combination buildings are popular here for a reason.

FAQs About Metal Garages and Carports

Do you have questions about metal carports and steel garages? Below are answers to common questions we see from buyers.

Is a metal carport cheaper than a metal garage?

Answer: Usually, yes. Less material. Less labor.

Can I enclose a carport later?

Answer: Often you can, but it’s easier if it’s planned that way from the start.

Do I need a permit for a carport or garage?

Answer: Depends on where you live. Garages are more likely to require permits.

What makes a structure a “carport” in code terms?

Answer: Open sides. That’s the big thing.

What size carport fits a full-size truck?

Answer: Around 12 feet wide and 25 feet long works for most trucks.

What size garage fits two vehicles plus storage?

Answer: A 24 x 30 garage is a common go-to.

Is a fully enclosed metal garage better for storms and snow?

Answer: Yes. Enclosure makes a real difference.

Should I choose vertical roof panels for heavy rain or snow areas?

Answer: Most of the time, yes. Water and snow shed better that way.

EMB Metal Buildings Is Your First Stop for High Quality Metal Buildings

Finding the right steel structure doesn’t have to be complicated. With EMB by your side, you’ll get the building type you need at a price you can afford. Our structures are built with quality steel components, engineered for local conditions, and designed to fit your exact use case.

Ready to start building? Call our experts at (208) 572-1441 for more information, or use our online tools to explore options and pricing.

People often toss around the word "gauge" when discussing metal buildings, but few stop to consider what it really means. For steel, its gauge is a system of determining how thick it is. The smaller the number, the thicker the material.

What Is Gauge?

Most metal buildings utilize 14-gauge steel for their framing. It’s light, sturdy, and can hold its own in most scenarios. However, some environments with higher wind speeds and snowfall demand thicker 12-gauge framing to carry the load and pass local building requirements.

And while you might not notice much of a difference in performance at first, that beefier framing makes it a lot harder for nature to bend or twist your structure out of shape.

Key Highlights

- 12-gauge = thicker and stronger

- 14-gauge = good for most small to mid-size builds

- Lower gauge = better wind and snow performance

- 12-gauge holds shape longer under stress

- Often comes with a better warranty

- Price bump is small compared to the upgrade in strength

Steel Gauge Chart

| Gauge | Inches | Millimeters |

|---|---|---|

| 8 | 0.164 in | 4.17 mm |

| 10 | 0.135 in | 3.43 mm |

| 12 | 0.105 in | 2.67 mm |

| 14 | 0.075 in | 1.90 mm |

| 16 | 0.060 in | 1.52 mm |

| 18 | 0.048 in | 1.21 mm |

| 20 | 0.036 in | 0.91 mm |

| 22 | 0.030 in | 0.76 mm |

| 24 | 0.024 in | 0.61 mm |

| 26 | 0.018 in | 0.46 mm |

| 28 | 0.015 in | 0.38 mm |

| 30 | 0.012 in | 0.30 mm |

How Gauge Impacts Loads

Thicker framing doesn’t just sound tougher. It is tougher. Heavier steel stands up better to snow buildup, hard gusts, and the added stress from longer spans.

Engineers run the numbers for wind and snow loads based on ASCE 7 standards. Using this system, buildings can be rated for anywhere from 115 to 170 mph winds and 20–60 psf snow loads.

The local requirements for wind and snow loads depend on location, open exposure, and roof pitch. For example, a building sitting on a hill or near the coast deals with more pressure than one behind trees.

Upgrading to 12-Gauge Framing

At what point should you consider upgrading?

- High Wind Speeds

If your metal building will sit in an area with high wind speed calculations, you may need to upgrade to thicker framing to prevent swaying or failure.

- Heavy Snow Regions:

If you expect to see your fair share of deep snows this winter, upgrading your framing thickness is a smart move.

- Longer, Bigger Buildings:

Longer spans put more stress on the frame of your pre-engineered metal building.

- Certification Needs

Higher wind or snow ratings often call for thicker 12-gauge.

- Lower Maintenance:

Thicker steel can last longer and require fewer repairs over the course of its life.

Cost and Warranty Changes with Framing Upgrades

You can expect a small price increase when you upgrade from 14-gauge to 12-gauge framing. You pay for thicker steel, heavier anchors, and reinforced braces to match it. Usually, you’re looking at around 10–15% more on the framing side.

However, that extra spend often gets you a longer rust-through warranty, sometimes 25 years instead of 20. The thicker galvanizing takes longer to wear down, especially in damp or coastal areas.

So, while the up-front cost stings a little, you’re getting fewer repairs, less movement, and a frame that won’t quit early. In the long run, it’s usually worth every bit.

Frequently Asked Questions about Framing Gauges for Metal Buildings

Do you have questions about framing gauge, and which thickness is best for you? Below, we’ve answered some of the questions we see on this subject the most:

Is 12-GA stronger than 14-GA?

Answer: Yeah. It’s thicker, heavier, and stiffer under load.

What’s the real thickness difference?

Answer: 12-ga steel is about 0.1046 inches thick, while 14-ga runs around 0.0747 in.

Does 12-GA automatically mean better wind or snow ratings?

Answer: Not by itself. The full design, including anchors, trusses, and layout, plays a role. But thicker framing helps you hit higher numbers.

Does the 20-year rust warranty only cover 12-GA?

Answer: Usually, the heavier gauge gets longer coverage. Some 14-ga options still offer 20 years, but 12-ga often goes a few years beyond that.

Your garage is more than a parking spot; it’s an extension of not just your home but also your personality. It speaks for itself. This is your storage hub, workshop, a space full of future potential & ideas, and definitely a home to your cars.

Quick Actions (Fastest Next Steps)

- Design & price online: Use the 3D Building Designer

- Get a Free Quote: https://www.engineeredmetalbuildings.com/contact-us/

- Call Now: (208) 572-1441

- Flexible payments: Financing | Rent-To-Own

TL; DR: Quick Takeaways

Essential facts you should know:

- Single Car: Think of a 12x20 as the absolute tightest fit. It'll do the job, but just barely. If you can, stretch it to a 14x24.

- Two Cars: Yeah, a 20x20 is what everyone builds. If you want a garage that works harder, aim for 24x24.

- Three Cars: A 32x22 works for three sedans. But let's be real, we drive trucks and SUVs now. Do yourself a huge favor and upgrade to 36x24.

- A Word on Doors: If you're going for two cars, fight for two separate 9-foot doors with a solid wall between them.

- Here's the Real Secret: The magic of a great garage isn't its width- it's its depth. That space behind where your bumper stops? That's your gold mine. Plan for extra room back there.

Choosing the right size isn’t just an instinctive decision or squeezing your car in; it’s about creating a functional space that works for your lifestyle and boosts your property’s future value.

Here’s a simple guide to help you understand the available garage sizes, door dimensions, and more, so you can be confident when you plan what fits you best!

Planning Tip (Before You Finalize Size)

Picking the Right Garage Size

Following are the steps that help decide the right garage size for you-Step 1: Measure Your Vehicles

Measure the dimensions of your vehicles and add a 3-foot in front & behind, and 2.5 feet on the sides. This gives ample space for ventilation, easy exit & entry with movable area.

Step 2: Choose Your Door Layout

The functionality of a garage depends hugely upon the entry & exit points. For two cars, options between a 16-foot-wide door or two separate 8-9-foot wide are ideal. Two doors provide a much cleaner look with a supportive center column, curbing weather issues and simplifying repairs.

Step 3: Plan for Depth & Storage Zones

Don't make the number one garage planning mistake: forgetting about the depth. Sure, your car fits now, but where does the lawnmower go? The bikes? The holiday decorations? By adding a few extra feet of depth- 24 to 26 feet total- you create a "buffer zone" at the front or back.

Want a Garage That Doubles as a Shop?

Garage Sizes by Uses

Here’s a detailed breakdown of standard garage sizes and their ideal use cases.1-Car Garage

- Minimal Fit (12'x20'): Fits your car, but that’s it. Getting in and out is a squeeze.

- Comfortable Pick (14'x24'): Room to open doors easily + space along the wall for bikes or storage.

- Door Tip: Go for a 10-foot-wide door- it makes pulling in much easier.

2-Car Garage

- 20x20 feet (Minimum): Fits two cars, but it's a tight squeeze. You'll be climbing out carefully to avoid dinging doors.

- Comfortable/ Recommended Size: 22 ft. x 24 ft. This is a significant improvement, offering more shoulder room between vehicles.

- Family’s Favorite: This is the size that actually works for real life.

- Door: A 16-foot-wide door or, two 9-foot-wide ones.

3-Car Garage

- ‘Standard’ Size: 32 feet x 22 feet. This layout typically fits three cars in a row, but depth can be tight for larger vehicles.

- Better/ Recommended Size: 36 feet x 24 feet. The extra width and depth are worth the investment. It comfortably accommodates three larger vehicles (like trucks and SUVs) and provides essential storage space. T-shaped layouts are also popular for a third bay dedicated to a boat or workshop.

4-Car Garage

- Baseline Size: Starts around 40 feet x 20 feet, but this is highly customizable.

- Common Layouts:

- Parallel (4-in-a-row): A long rectangle, ideal for straightforward parking.

- Double-Deep (Tandem): Two bays deep, perfect for storing seasonal vehicles or creating a dedicated workshop space behind daily drivers.

- With Traffic Lanes: For easy manoeuvring of boats or RVs, include extra width for turning lanes.

Also Read: 30x40 Metal Buildings

Ready to see pricing ranges?

Garage Door Sizes Explained

The right door is as important as the garage itself. Use this [matrix](/garage-door-size-chart) as your guide.- 1 Car: a 9’ or 10’ door’s great.

- 2 Cars: a 16’ door’s standard.

- Door Height:

- Standard: 7 feet. Often too low for modern vehicles.

- Recommended: 8 feet. This is a smart upgrade that easily clears lifted SUVs, trucks with roof racks, and minivans.

Attached Vs. Detached Garages

- Attached Garage: Offers direct access to the home as well as convinience. It offers superior climate control and is usually less expensive to construct. It can, however, be noisy.

- Detached Garage: Offers excellent segregation, perfect for noisy hobby areas, and rental apartments. Prefabricated metal detached garages, are ready in a matter of weeks, and gives you a significant advantage in terms of lead time and construction.

Get Help Choosing the Right Layout

- Get a Free Quote: https://www.engineeredmetalbuildings.com/contact-us/

- Call: (208) 572-1441

What’s the Right Garage Size?

| Garage Type | Minimum Dimensions | Ideal Dimensions | Perfect For |

|---|---|---|---|

| 1-Car | 12' x 20' | 14' x 24' | A single car. |

| 2-Car | 20' x 20' | 24' x 24' | Families with two cars, additional storage. |

| 3-Car | 32' x 22' | 36' x 24' | Bigger families, trucks, or anyone with hobbies or growing needs. |

| 4-Car | 40' x 20' | Custom-made (e.g., 40'x30') | Car collections, boats, or massive equipment or storage. |

Want to lock in a plan today?

- Design it in 3D: https://engineeredmetalbuildings.sensei3d.com/

- Ordering steps: https://www.engineeredmetalbuildings.com/ordering-process/

Let’s Build a Garage You’ll Love!

Getting stuck with a garage that you regret later is a real thing. Use this guide to make an informed choice, or contact us to receive a quote for a space that truly suits your needs.Call: (208) 572-1441

Request a Free Quote

We’re here to guide you, clarify your doubts, and help you choose what’s best for you!

The roof over your head is a deciding factor in your peace of mind and sense of security. Choosing the one that's not just sturdy, but actually fits you perfectly is one of the most critical decisions you'll make. It's about aesthetics, what you feel most comfortable and secure in, as well as performance, durability, and long-term value. The style and orientation of your roof panels directly impact how your building handles rain, snow, wind, and debris.

This guide will break down the differences between Regular, A-Frame Horizontal, and Vertical roof styles to help you make an informed choice that ensures better functionality and protects your investment for years to come.

TL; DR: Quick Takeaways

- Vertical Roof is the top performer for harsh weather (snow, heavy rain, high wind) and longer buildings, but it costs more.

- Regular Roof is the most budget-friendly option, best suited for mild climates and smaller structures.

- A-Frame Horizontal offers the classic house-like look at a lower cost than vertical, but shares the limitations of horizontal panels.

- Building length over 31 feet? Choose a Vertical roof to minimize leak-prone seams.

- Panel orientation matters: Vertical panels shed water and debris dramatically better than horizontal panels.

- Roof noise is solved by insulation, not the roof style itself.

Regular vs A-Frame vs Vertical Roof Style

| Aspect | Regular Roof (Rounded Horizontal) | A-Frame Horizontal (Boxed-Eave) | Vertical Roof |

|---|---|---|---|

| Description | Simple design with curved eaves; panels run horizontally. | Traditional "house-like" appearance; panels run horizontally. | Panels run from ridge to eave; requires a standing seam or batten cap. |

| Pros |

|

|

|

| Cons |

|

|

|

| Best Use Cases |

|

|

|

| Relative Cost | $ | $$ | $$$ |

How Panel Orientation Affects Drainage & Maintenance

The direction your roof panels run isn't just for looks- it fundamentally changes how your roof performs.

- Drainage: Vertical panels channel rain, snow, and pine needles off the roof. Whereas, Horizontal panels have laps where water jumps across, trapping leaves & debris, leading to stagnant pools and corrosion.

- Gutters: The straight, downward flow of a vertical roof aligns with the gutters and downspouts, which minimizes messy splash-back on your the doors & siding. Horizontal roofs can cause water to sheet unevenly off the eave.

- Noise: Worried about rain being louder on a metal roof? The orientation matters less than you think. Proper insulation is the key. A layer of 2-inch fiberglass or spray foam effectively eliminates the "drumming" effect, making any metal roof comfortable and quiet.

What Are Three Metal Building Roof Styles?

Understanding the core options is your first step.Regular (Rounded Horizontal): Most common and economical.

- It's got curved eaves and horizontal panels- simple and fast to install.

- Suitable for mild climates with low wind and rain

- Not a great choice if you're constantly dealing with heavy snow in your area. There's a risk of leaks at various horizontal seams.

A-Frame Horizontal (Boxed-Eave): Want the look of a traditional house roof?

- Gives you that classic peaked appearance. However, the panels still run horizontally.

- Great for curb appeal in mild zones, but it shares the same performance and length limitations (typically capped around 31') as a Regular roof.

Vertical Roof: This is the premium, high-performance option.

- The panels run vertically from the ridge down to the eaves. This system requires additional structural support (hat channels or purlins) and a special ridge cap.

- Best for handling snow, rain, and high winds, and is essential for longer buildings, while versatile for all.

- The enhanced performance comes with a higher price tag due to the extra steel and labor involved.

Also Read: Standard Garage Sizes

When to Choose Which Style?

Your local climate, budget, and building dimensions will point you to the right choice.

- If building length > 31′: Choose Vertical- avoids dozens of leak-prone horizontal seams across the slope of your roof.

- If heavy rain/ snow/ wind or lots of trees: Choose Vertical- gives superior drainage and added structural strength, worth the investment.

- If mild climate + tight budget: Choose Regular or A-Frame Horizontal- if you want it to match the look of your home.

Cost, Maintenance, and Payback

Why Does a Vertical Roof Cost More?

The price difference comes down to materials and labor. A vertical roof system requires additional structural components like hat channels or purlins to create the vertical seams, a more complex ridge cap, extra trim, and more fasteners. This also translates to more labor time for installation compared to the straightforward panel laying of a horizontal roof.

The Maintenance Reality

Your long-term cleaning effort is also affected by the style. A horizontal roof will need more periodic blowing off or rinsing to clear debris trapped in the panel laps. A vertical roof, with its efficient shedding, typically means fewer ladder trips and less worry about debris-related moisture and damage.

Our Final Word:

At EMB, we understand that your roof is not just a building structure, but your protective shield. We take metal buildings seriously and ensure that you find yourself the sturdiest, most durable and long lasting solution with minimal upkeep.Explore your options with our interactive 3D Builder, or speak directly with our team to get started on your project.

You want straight answers and practical specs. Here’s the real-world guide contractors, farmers, and homeowners use when planning a 30×40 (1,200 sq ft).

Want an itemized quote for your zip code?

Use our 3D Design Tool or call (208) 572-1441.

TL;DR

- Typical 2026 price for a 30×40 (1,200 sq ft):

DIY kit: about $18,000–$30,000

Installed: about $28,800–$51,600

Complex loads or premium options can push totals higher. - Concrete slab (4–6 in): about $7,200–$14,400 installed, depending on region and finish.

- Lead times: many tubular cold-formed building installs land in the 4–10 week range depending on region and season.

- Permits: many jurisdictions use I-Codes with local amendments and design loads tied to ASCE 7.

Start by confirming your local wind/snow requirements: Check snow & wind loads. - Financing: options vary, but many buyers use financing for the building + slab. See Financing and Rent-to-Own.

What Fits Inside a 30×40

1,200 sq ft is a popular footprint with a lot of flexibility. Clear span is common. A 10–12 ft eave height covers most pickups with racks.

| Use case | Typical layout | Notes |

|---|---|---|

| Two cars + workshop | Two 10×10 roll-up doors on gable end, 1 walk door, 1–2 windows | 12 ft center aisle works well for tool benches |

| Truck + tractor bay | One 12×12 roll-up, one 10×10, 12–14 ft eave | Consider vertical roof and heavier framing in snow/wind areas |

| Small business shop | 1 or 2 10×10 doors sidewall, 1 office corner | Insulate roof at minimum to help control condensation |

| Storage | Single 10×10 door, no windows | Cheapest enclosed configuration |

Door price reality check:

- A 10×10 roll-up commonly prices around $1,100–$1,300

- A 12×12 door is often $1,300–$1,900+ depending on wind rating and insulation

Related: If you’re building an enclosed vehicle/work space, start here: Metal Garages.

2026 Price Breakdown: DIY Kit vs Installed

National ranges

| Scope | Price per sq ft | 30×40 total |

|---|---|---|

| DIY kit only | $15–$25 | $18,000–$30,000 |

| Installed shell | $24–$43 | $28,800–$51,600 |

Ranges reflect typical market guides and assume “average” wind–snow loads. High-wind coasts and heavy-snow counties run higher.

What moves your price

| Feature | Typical impact on a 30×40 |

|---|---|

| Frame gauge upgrade (example: 14-ga to 12-ga) | Often increases cost, but improves strength in higher-load areas |

| Roof style (horizontal to vertical) | Often adds materials/labor, but sheds water and snow better |

| Eave height (every 2 ft taller) | More steel and bracing |

| Roll-up doors (size + wind rating) | Door size and wind rating can swing pricing significantly |

| Walk door (36×80 steel) | Adds cost; fire-rated or glazed doors cost more |

| Windows (3×4 typical) | Adds cost; thermal packages cost more |

| Insulation (roof-only vs full wrap) | Roof insulation helps condensation control; full wrap improves comfort |

| Engineering/certification | Often required for permitting in strict wind/snow/seismic areas |

Also read: Metal Building Roof Styles

Engineering & Permits by Region

The short version: your local building department (AHJ) typically enforces an I-Code edition with local amendments and structural loads tied to ASCE 7. Coastal areas care about wind and debris exposure. Mountain and northern areas care about ground snow load. Seismic matters in parts of the West.

Before you finalize a design, confirm your local hazards: Check snow & wind loads.

Wind and snow basics to plan for

- Hurricane-prone coasts: doors and connections often need wind ratings to match local requirements.

- Snow country: ground snow loads can vary widely by county and elevation, not just by state.

Permit-ready checklist

- Site plan with setbacks, driveway, and utilities marked

- Foundation detail (slab or piers), plus frost depth notes if applicable

- Signed and sealed drawings showing design loads per your AHJ

- Door and window wind ratings (where required)

- Anchoring and uplift details

- Energy or insulation notes if required by local amendments

Helpful next step: Site Preparation Guide and Ordering Process.

State-by-state quick notes (fast scan)

- AL: Mixed wind inland, higher along Mobile–Baldwin. Ask for door wind ratings on the coast.

- AK: High snow and deep frost. Sealed foundation and roof load calcs often expected.

- AZ: Low snow except high country. Check local wind in open terrain.

- AR: Moderate wind. Frost depth often 12–24 in.

- CA: Seismic and strict energy requirements in many areas.

- CO: Snow varies by county and elevation, can be very high in the Rockies.

- CT: Snow and energy requirements are strict.

- DE: Coastal wind exposure near the bays.

- FL: Hurricane wind and debris region, plan for wind-rated doors and connections.

- GA: Moderate wind, shallow frost.

- HI: Wind and corrosion protection matter on the coasts.

- ID: Snow and seismic both matter depending on county.

- IL: Snow and deeper frost common.

- IN: Snow moderate, frost depth often 30–36 in.

- IA: Snow moderate.

- KS: Wind exposure in open terrain.

- KY: Mixed conditions, check local amendments.

- LA: Gulf wind and uplift on the coast.

- ME: Higher snow loads, plan insulation and ice management.

- MD: Coastal wind in east, more snow inland/west.

- MA: Higher snow and strict energy code.

- MI: Snow and deeper frost typical.

- MN: High snow and deep frost, verify snow load and footing depth.

- MS: Moderate wind, higher along the coast.

- MO: Mixed winds, frost increases northward.

- MT: High snow in mountain counties.

- NE: Wind exposure, snow varies.

- NV: Snow in the north/high elevations, wind in basins.

- NH: Higher snow, sealed roof calcs common.

- NJ: Coastal wind along shore, more snow inland.

- NM: Wind exposure, snow at elevation.

- NY: Snow upstate/north; NYC uses its own code administration.

- NC: Coast has wind, mountains have snow, piedmont moderate.

- ND: High snow and deep frost.

- OH: Snow moderate, frost depth often around 32 in.

- OK: Wind exposure, tornado-related design conversations common.

- OR: Seismic in western valleys, snow at elevation.

- PA: Snow varies, energy code applies.

- RI: Coastal wind, more snow inland.

- SC: Coastal wind increases toward the Lowcountry.

- SD: High snow and frost depth.

- TN: Mixed conditions, check local requirements.

- TX: Gulf wind on coast; Panhandle/Hill Country can differ (wind and occasional snow).

- UT: Snow in mountains and seismic along the urban corridor.

- VT: Higher snow, sealed drawings common.

- VA: Coastal wind east, snow in the Appalachians west.

- WA: Seismic west side, snow in Cascades and northeast.

- WV: Snow at elevation, moderate elsewhere.

- WI: Snow and deep frost typical.

- WY: High wind exposure and mountain snow.

Three Real-World 30×40 Configurations

| Package | Who it fits | Spec highlights |

|---|---|---|

| Good – Workhorse Garage | Homeowners, small farms | 14-ga frame, 10 ft eave, vertical roof, (2) 10×10 doors, (1) walk door, roof insulation only |

| Better – Shop-Ready | Contractors, hobby shops | 12-ga frame, 12 ft eave, vertical roof, (1) 12×12 + (1) 10×10, (2) windows, more insulation |

| Best – Wind/Snow Certified | Coasts or mountain counties | Engineered for AHJ loads, upgraded bracing, wind-rated doors, full wrap insulation, heavier anchors, sealed plans |

Lead Times & Delivery Factors

- Standard installs: often 4–6 weeks in normal seasons, and 8–10+ weeks in peak or remote areas. Weather and permitting can add time.

- Rigid-frame PEMBs: design–fab–ship often 6–12+ weeks after approvals. Plan ahead for anchor bolt placement and slab cure time.

Avoid delays: Site Preparation.

Financing & Price-Lock Options

- Financing: explore EMB’s options here: Financing

- Rent-to-Own (RTO): learn how it works: Rent-to-Own

- Price-lock: many buyers lock pricing with a deposit while they finalize site prep and permits. Ask what the lock period covers and get it in writing.

Configure a 30×40 and Get an Itemized Quote

Ready to see your exact number with your doors, height, loads, and foundation plan?

- Use the 3D Design Tool

- Or call (208) 572-1441

- Or send details here: Contact Us

If you message your zip code, eave height, door sizes, and whether you need a slab quote, we’ll return an itemized quote with certified specs for your county.

RV carport height isn’t something you want to eyeball or guess. Being off by even a small amount can turn into a daily hassle. Before committing to a design, the smartest move is to measure your RV yourself and work from real numbers instead of assumptions.

Key Highlights

- RV height should always be measured by hand, not pulled from a brochure

- Roof accessories often make RVs taller than expected

- Clearance matters just as much as the RV’s actual height

- Roof style changes how much usable space you have inside the carport

- Planning ahead helps avoid rebuilding later

Finding Your RV’s Overall Height

This part matters more than anything else. Many RV owners assume they already know their rig’s height, but real-world measurements are often different. Add-ons, ground conditions, and even tire wear can change things. Taking a few minutes to measure properly now can prevent expensive mistakes later.

- Measure RV Height

Park your RV on flat ground and grab a tape measure. Measure straight up from the ground to the tallest point on the roof. This usually isn’t the roof itself, it’s the air conditioner, vent cover, antenna, or satellite dish. Measure slowly and double-check your work.

- Add Clearance

Once you have the true height, don’t stop there. Add some clearance. Most people aim for an extra 6 to 12 inches. That buffer helps with uneven slabs, suspension movement, and pulling in without stress. It also gives you flexibility if you add gear later.

- Convert RV Height to Recommended Leg Height

Your RV height plus clearance gives you a target number. From there, roof style and pitch come into play. Those factors determine how tall the legs need to be so the lowest point of the roof doesn’t interfere.

Roof Style and Usable Height

Two carports can have the same leg height but very different interior clearance. The roof shape changes everything. Let’s look at some of the common styles and how they affect your interior height:

- Regular Roof

Regular roofs have a softer curve and lower pitch. You get decent height in the middle, but usable clearance drops near the sides. It works for shorter RVs, less so for taller ones.

- A-Frame Roof

A-frame roofs use a sharper pitch. That gives you better center clearance without dramatically increasing leg height. It’s a common upgrade when RV height is close to the limit.

- Vertical Roof

Vertical roofs have the steepest pitch. They offer the most usable height overall and handle rain and snow better. For tall RVs, this option leaves the most breathing room.

Common RV Height Ranges

Most RVs fall into a general height range, but accessories can push them higher. These ranges give you a starting point.

| RV Type | Typical Height | Suggested Carport Leg Height |

|---|---|---|

| Travel Trailer | 10’–11’ | 12’ |

| Fifth Wheel | 12’–13’ | 14’ |

| Class C Motorhome | 11’–12’ | 13’–14’ |

| Class A Motorhome | 12’6”–13’6” | 14’–16’ |

A Checklist for RV Carport Prep

Before installation, it helps to slow down and look at the site itself. A solid plan makes the build smoother and prevents last-minute changes that cost time or money.

- Site prep – Make sure the ground is level and accessible

- Slab thickness – Concrete should support both the RV and anchors

- Drainage – Water should flow away from the pad, not pool

- Gutters – Helps control runoff and protect the slab edge

- Future needs – Consider taller RVs or partial enclosures later

Design Your RV Carport the Right Way with Our 3D Designer

Designing on paper only gets you so far. Using the 3D designer lets you actually see how leg height, roof pitch, and layout work together. You can tweak dimensions, change roof styles, and catch issues before anything is built. All from home, on your schedule.

Try our 3D Designer to get a custom RV carport quote matched to your zip code.

Carport Height Matters

RV carport height isn’t about picking a random number. It’s about knowing your RV, allowing for clearance, and choosing a roof style that gives you usable space. Measure carefully. Plan for the future. When those pieces line up, your finished carport fits the way it should, without stress or second guesses.

Want to know more about picking the best height for your RV carport? Call our experts at (208) 572-1441 to get started.

When buyers start talking about building height, the conversation can get confusing fast. One person is thinking about wall height. Another is focused on the roof peak. Someone else just wants enough room inside to park equipment. All of those ideas fall under “height,” but they’re not the same thing.

On top of that, local building departments set rules that can override personal preferences. Those rules are usually tied to wind exposure and snow load. Whatever height you settle on has to work within those limits.

Key Highlights

- Building height is measured in more than one way

- Sidewall height doesn’t always equal usable space

- Roof pitch affects total height more than expected

- Doors often determine minimum wall height

- Local codes influence allowable height

- Wind and snow loads are tied to height calculations

Metal Building Heights

Not all height measurements serve the same purpose. Some are used when ordering a building. Others come into play during engineering and permitting. Understanding the difference early helps avoid revisions later. Below, we break down these metal building heights:

Sidewall Height

Sidewall height is measured from the finished floor to the eave. This is the number most buyers reference when choosing a building. It impacts door placement and wall clearance, but doesn't include the roof structure.

Peak Height

Peak height runs from the floor to the highest point of the roof. It changes based on roof pitch and building width. Zoning regulations often reference this measurement.

Clear Height

Clear height describes the open vertical space inside the building. Framing, purlins, and insulation reduce it slightly. This is the height that matters for lifts, racks, and tall vehicles.

Mean Roof Height

Mean roof height is the average between the eave and the peak. Engineers use it when calculating wind and snow loads. It's rarely discussed by buyers, but it matters behind the scenes.

Roof Pitch and Type

Roof design plays a quiet but important role in overall building height. A small change in pitch can add noticeable height at the peak. Roof type also affects how weather loads are handled.

Gable Roof

Gable roofs slope up from both sidewalls and meet at the ridge. They're common because they balance loads well and provide extra height near the center.

Single-Slope Roof

Single-slope roofs rise from one side to the other. They're often chosen when height limits apply or when drainage needs to move in one direction.

Gambrel Roof

This roofing type offers a bit more headroom thanks to its four-panel roofs that are arranged in a barn-like arc.

Common Roofing Styles

- Regular Roofing: This is your basic roofing style. It’s economical and great for general storage, but isn’t designed to handle more than moderate weather.

- A-Frame Roofing: This roof features a steeper pitch and is much more suited for rain and snow.

- Vertical Roofing: Vertical roofing features vertically arranged panels that allow snow and storm debris to slide off your roof. It's one of the most expensive options, but it provides the best functionality.

Door Height and Equipment Clearance

Doors are where height issues usually show up first. A building can seem tall enough until tracks and framing are installed, so planning for clearance avoids that problem.

Roll-up Door Height

Roll-up doors need space above the opening for tracks. A door listed at 12 feet typically requires additional wall height.

Framed Openings

Framed openings allow flexibility in door size and placement. They also affect how loads are distributed around the opening.

Oversized Vehicles

Taller vehicles, such as RVs, trailers, and motorhomes, require more than door clearance alone. Interior framing and roof slope reduce usable height.

Choosing the Right Height by Use

Height should match how the building will actually be used. Storage needs, access, and future plans all factor in.

| Building Type | Typical Height Range | Common Use |

|---|---|---|

| Residential Metal Garages | 8’–10’ | Vehicles and workshops |

| RV Storage | 12’–16’ | Motorhomes and trailers |

| Metal Barns | 10’–14’ | Equipment and livestock |

| Commercial Metal Buildings | 12’–20’+ | Operations and storage |

Why Building Height Matters for Wind and Snow

Building height affects how wind and snow interact with the structure. Taller walls catch more wind. Roof height changes how snow accumulates. Local building officials account for this when setting requirements.

- Wall height impacts wind exposure

- Roof height affects snow drift (ground snow loads map)

- Mean roof height is used in load calculations

- Taller buildings may need added bracing

EMB Metal Buildings can help guide you through these requirements and plan a building that meets local codes. Call us today at [phone number] for more information.

Quick Height Planning Checklist

Before finalizing height, it helps to think through real-world use.

- Purpose of the building

- Door sizes

- Interior clearance needs

- Local zoning limits

- Wind and snow load rules

- Roof pitch selection

Design Your Own Building in 3D with EMB Metal Buildings